After working together on the One Week Wonder CH750 build at EAA Airventure Oshkosh in 2014, the ‘Field Team’ have worked together on many projects – providing technical support, field service, engines, spares, training and more to their customers around the world. As technology has enabled greater international co-operation and collaboration, the ‘Field Team’ have taken this one step further to bring the best in support to OEMs and homebuilders in their working areas – hand-in-hand to the benefit of the end user.

Jonathan and Patricia Porter (Metal Seagulls Ltd, UK) are in daily contact with Phil Cronje (Bundu Aviation, S.A.) to ensure that their combined field experience of over sixty years in light aviation, around the world, is made available to support their clients across the UK, Iceland, Ireland, West Africa, South Africa and the COMESA states as well as the Falkland Islands and several other ‘unique aviation experience’ locations. Not only have the team all been ULPower factory trained but they have built and flown many many aircraft themselves, and have a clear understanding of the needs of the OEM and homebuilder when it comes to the industry leading, reliable and dependable powerplant options available from ULPower Aero Engines.

“I started my career in CNC engineering and have been involved in parts production for everything from aerospace to motor-racing, HVAC to ordnance, racking systems to pneumatic precision vices. I have developed custom aviation solutions for crop-spraying and surveillance as well as humanitarian supply drop and photo-video missions. Having been factory trained with Rotax, ULPower and Superior. I have a thorough understanding of the needs of a reliable powerplant appropriately installed to meet the mission requirements – whether that be ‘a local leisure flight’ or a ’10 hour airborne surveillance mission’. With around 5000 hours of flight time, being an aircraft inspector for both the UK LAA (Light Aircraft Association) and the UK BMAA (British Microlight Aircraft Association), and having been a test pilot for a major aircraft engine manufacturer, I know that this team offers a world leading product with outstanding support to those who value and trust the thrust giver for their flight. I offer support and training in English and French, to meet the needs of clients across the ECOWAS/CEDEAO region.” Jonathan ‘Yaw’ Porter, Director, Metal Seagulls Ltd

“With a solid background in engineering as a product development engineer, I found my passion in aviation with IFR and twin engine training – as well as test pilot approvals. My factory trained opportunities include Jabiru S.A., ULPower and Rotax iRMT (Heavy). Throughout my aviation career I have been extensively involved in prototype development and one-off projects with a range of airframe OEMs and homebuilders around the world. As a ‘Factory Approved Maintenance technician’ for several OEMs, I find myself travelling many thousands of miles each year to troubleshoot and resolve issues based on my extensive field experience. (including Ghana, CAR, Kenya, Zambia, Mozambique, Namibia, Botswana, SA, Lesotho, Panama, China…). I am fluent in both English and Afrikaans and get by with a little help from my friends in French too! With my strong background in rural, off grid, problem solving, and having worked ‘hands-on’ in a number of OEM facilities for problem solving, I regularly fly into remote stations for aircraft maintenance and hands-on training of field technicians. Whether working on a remote mining station or in an air-conditioned hangar at a major airport, I always find pleasure in ensuring that each aircraft engine is maintained to the highest standards and every installation adapted to meet the climatic and mission specific needs that often arise.” Philip Cronje, Director, Bundu Aviation, South Africa

“Having started on an aviation and technology apprenticeship, in Ghana, West Africa, I have been privileged to become the first civilian woman in Ghana to obtain a pilots licence as well as the first woman to be factory trained in Rotax as well as ULPower Aero Engines. Since moving to the UK in 2015, I am honoured to have become the first black female aircraft inspector for the LAA and also for the BMAA, and am privileged to manage the non-certified aircraft maintenance and home-builder assistance centre at Haverfordwest Airport, Pembrokeshire, Wales, UK. I regularly run training courses on engine and airframe matters, provide technical training and inspirational presentations to encourage more women and minorities into aviation and engineering. I speak English am fluent in a number of West African languages (and am now learning Welsh too), and understand the need for appropriate engines for a wide variety of applications – whether for leisure or for humanitarian and agricultural missions.” Patricia Mawuli Porter OBE, Director, Metal Seagulls Ltd

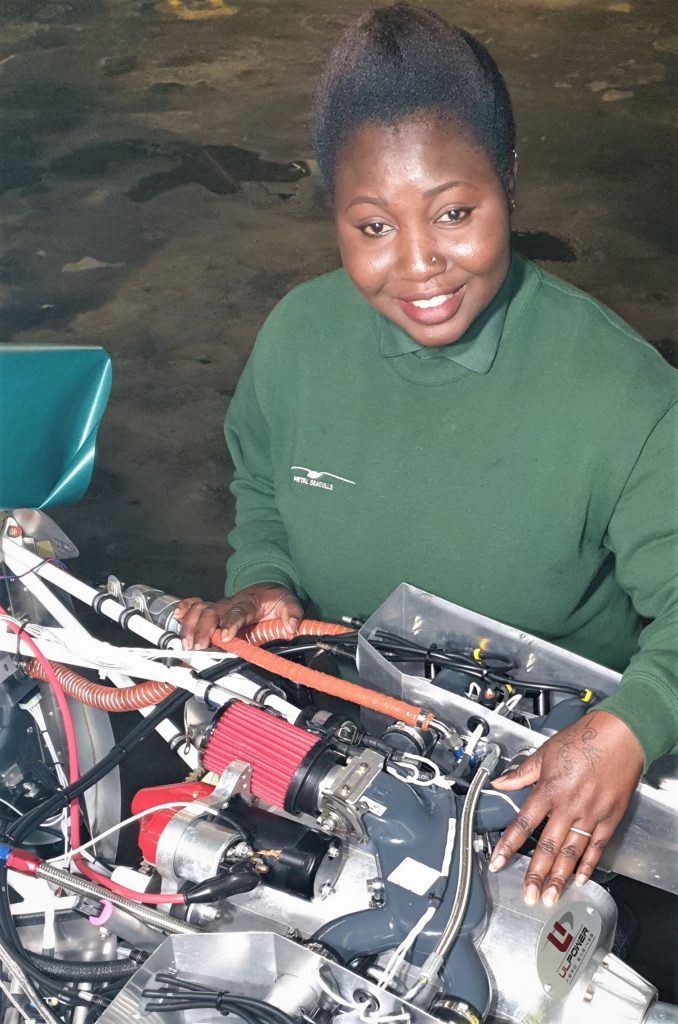

Layney

Layney has recently completed her engine training at ULPower HQ, and is on a 4-year apprenticeship route to a degree in engineering with us. Layney has a passion for aviation and machining and is the working towards taking the lead in our CNC production cell where we provide a range of custom parts for home builders and production series for a wide range of OEMs. Here she is working on a custom panel for ULPower engine sub-panel. When a part is needed, we all work collaboratively to ensure that a timely and appropriate component is expedited to our clients, regardless of their geographical location.